At Maine Woods Company, we use a variety of industry leading, state of the art equipment to achieve maximum efficiency and produce the highest quality products. Even with the best equipment, it is our skilled employees that make everything function smoothly. View our gallery to see photos of our equipment or scroll down to see our equipment in action!

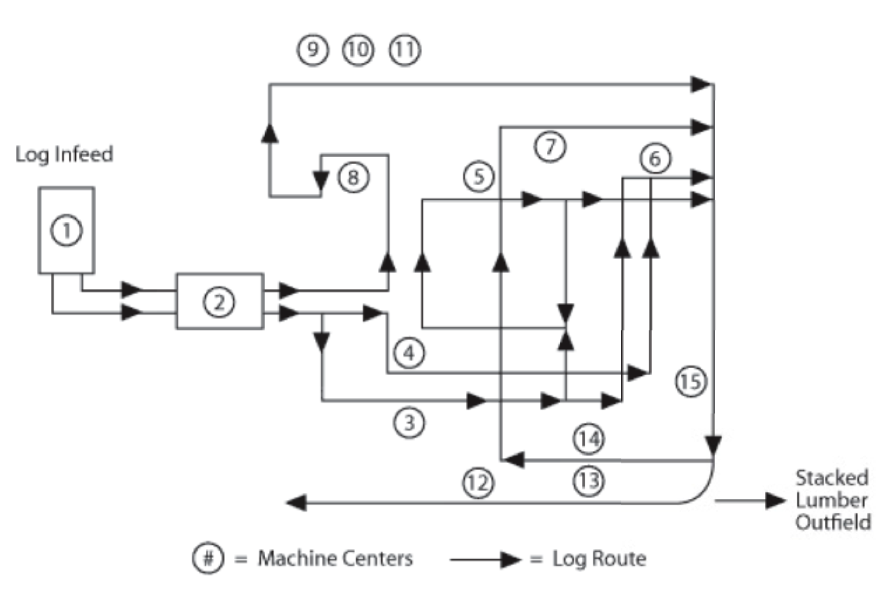

- Log transfer

Area where logs are received from yard - Debarkers

35” Valon Kone 5-Arm Ring Debarker and RosserHead Debarker

Debark logs for sawing - Maximill

2-Albany 5′ bandsaws coupled with 2-Coe/Ahlstrom canter heads (chipper knives and saw blade combination)

Saws logs between 6″-15″ in diameter

Capacity of 3 logs/min - Headrig with carriage

McDonough 7-8A 17 degree tilted bandmill and Corley 17 degree tilt super heavy duty straight line, 36″ opening, 3 headblock carriage with 3-D scanning and linear positioner

Saws logs over 16″ in diameter 8′-14’ lengths

Capacity of 1 log/min - Resaw

McDonough 7-8A vertical band with precision moveable linebar and return “merry-go-round”

Chooses best face to cut from headrig cants

Capacity of 9-10 lumber pieces/min - Combo-Edger

8″ X 60″ Schruman, split press roll, 500hp (2-250hp) bottom arbor, #3 splined, climb cut edger

Saws cants from Maximill, Headrig, and Resaw

Capacity 4 to 6 cants/min and 11 lumber pieces/min - Board Edger

Schruman 3-saw shifting edger with Servo controls

Edges board to 4 sides to maximize grade and recovery

Capacity of 30 pieces/min - Minimill

Composed of a 5′ Albany double-cut band headrig, 3-D scanning, a Serig hydraulic powered 2-knee carriage with a 24″ opening complete with tempasonic hydraulic cylinders, a 2 saw short wood edger, and a 24″ log turner

Saws logs from 6″ to 30″ in diameter with lengths 4′ to 8′

Up to 1/2 log/min - Planer (Downstairs)

Two-sided

Planes 1″ to 36″ wide and 4′ to 14′ lengths

Added value for some customers - Compressor Room (Downstairs)

Variable output and frequency drive

Control on demand

Provides for some mill heat on demand

$43,000 state rebate for electrical savings initiative - Rip Line (Downstairs)

Capacity of 30 MBF/day

Added value initiative in poor market - Bin Sorter

A complete 62 bin sorter

Sorts lumber by grade, length and thickness

Lumber end stamped with grade, grader and bin number - Trimmer

Precision drop trimmer with Autolog controls

Capacity of 80 pieces/min

Trims lumber to maximize recovery and grade

New dust collection system - Hula Saw

Grades and trims cants to lengths

Recycles boards for regrading and edging - Grading Table

3 NHLA trained graders

Capacity of 80 pieces/min

Initial lumber grading station for mill

Stackers

A lumber stacker for solid or kiln ready packages

Kilns

Two 50,000 BF and four 100,000 BF American Wood Dryers track kilns with protected infeed and outfeed. Total dry kiln capacity of 500 MBF

Dry Line—Maine Woods Company recently installed a new dry line facility which became operational mid-September 2015. The line is manufactured by Piche and is capable of processing 60,000 BF of dry lumber per shift, equivalent to 15.5 MMBF annually.Total sawmill production capacity of 18 MMBF/year

Maine Woods Company Overview Video